Evonik

Evonik is the world’s only fully backward-integrated producer of high-selectivity separation membranes. Thanks to the group’s many years of expertise in polymer chemistry, Evonik is able to adjust the membrane properties already at the development stage of the base material—the high-performance polymer—to produce especially selective and robust membranes that can withstand extreme pressures and temperatures.

Description

SEPURAN®: Efficient Gas Separation using Hollow-Fiber Membranes

Evonik boosts the chemistry of high-performance polymers into highly efficient gas separation membranes SEPURAN®.

SEPURAN® stands for customized hollow fiber membranes for efficient gas separation. Biogas upgrading, nitrogen generation and helium recovery are just three of the many applications for SEPURAN® products. Each product is tailored exactly to the specific application. SEPURAN® Green, for example, is ideally suited for biogas upgrading because of its high CO2 / CH4 selectivity. SEPURAN® N2, on the other hand, was developed especially to recover nitrogen.

Although the areas of application for SEPURAN® products differ considerably, the products all have one thing in common: they are the most important part of the upgrading system, no matter whether it is for biogas, air, or technical gases. With their high selectivity and capacity, they are effective in making the upgrading process as efficient and economical as possible. This is not only a result of the very low energy consumption. No other auxiliary materials, such as water or chemicals, are needed. Consequently, SEPURAN® helps conserve resources and protect the environment. SEPURAN® Green was a worthy winner of the 2014 German Innovation Prize for Climate and the Environment (IKU), which is awarded by the German Federal Ministry for the Environment.

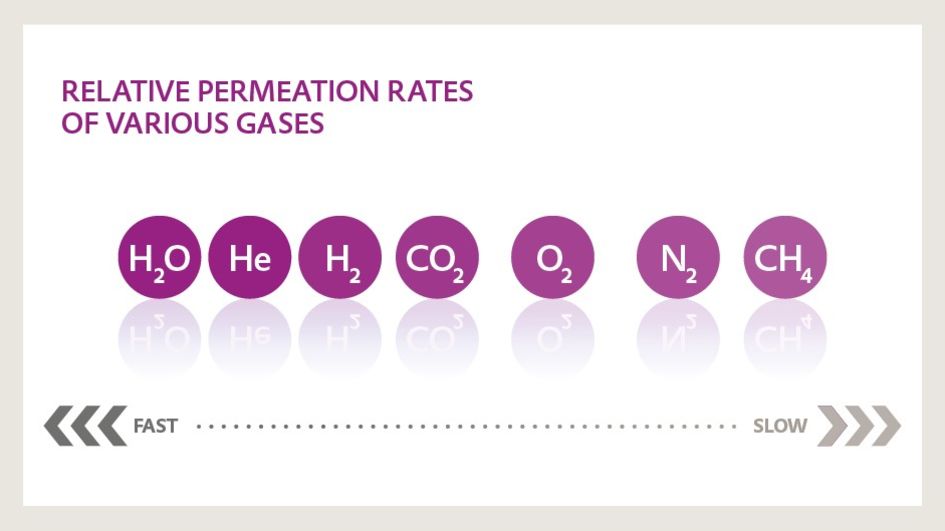

Principle of selective permeation for gas separation

Gas separation membranes work according to the principle of selective permeation through the membrane surface. The permeation rate of each gas depends on its solubility in the membrane material and on the diffusion rate of the gas.

Gases with high solubility and small molecules pass through the membrane very quickly. Less soluble gases with larger molecules take more time to permeate the membrane. In addition, different membrane materials separate differently. The driving force needed to separate gases is achieved by means of a partial pressure gradient.

Partial pressure gradient

The driving force for a gas to permeate through a membrane is the partial pressure difference; in other words, the partial gradient between the inside of the hollow fiber (retentate side) and the outside of the hollow fiber (permeate side). The greater the difference, the more gas permeates through the membrane. For example, if carbon dioxide and methane are being separated, as is the case with biogas upgrading, carbon dioxide permeates through the membrane very quickly while the methane tends to be held back.

The separation capability through the membrane is unaffected by process conditions – even with partial pressures of up to 20 bar, which is the case in biogas upgrading.

Leading innovation due to fully backward integration

The SEPURAN® high performance membranes are being produced and marked as modules and cartridges. Evonik is not a plant construction company working closely together with plant and machinery installation companies and engineering partners to find the best possible system solution for you.

For more information, please visit: https://www.membrane-separation.com/en

Services

- Equipment suppliers