Key Carbon Reduction Development Project in Suzhou, China

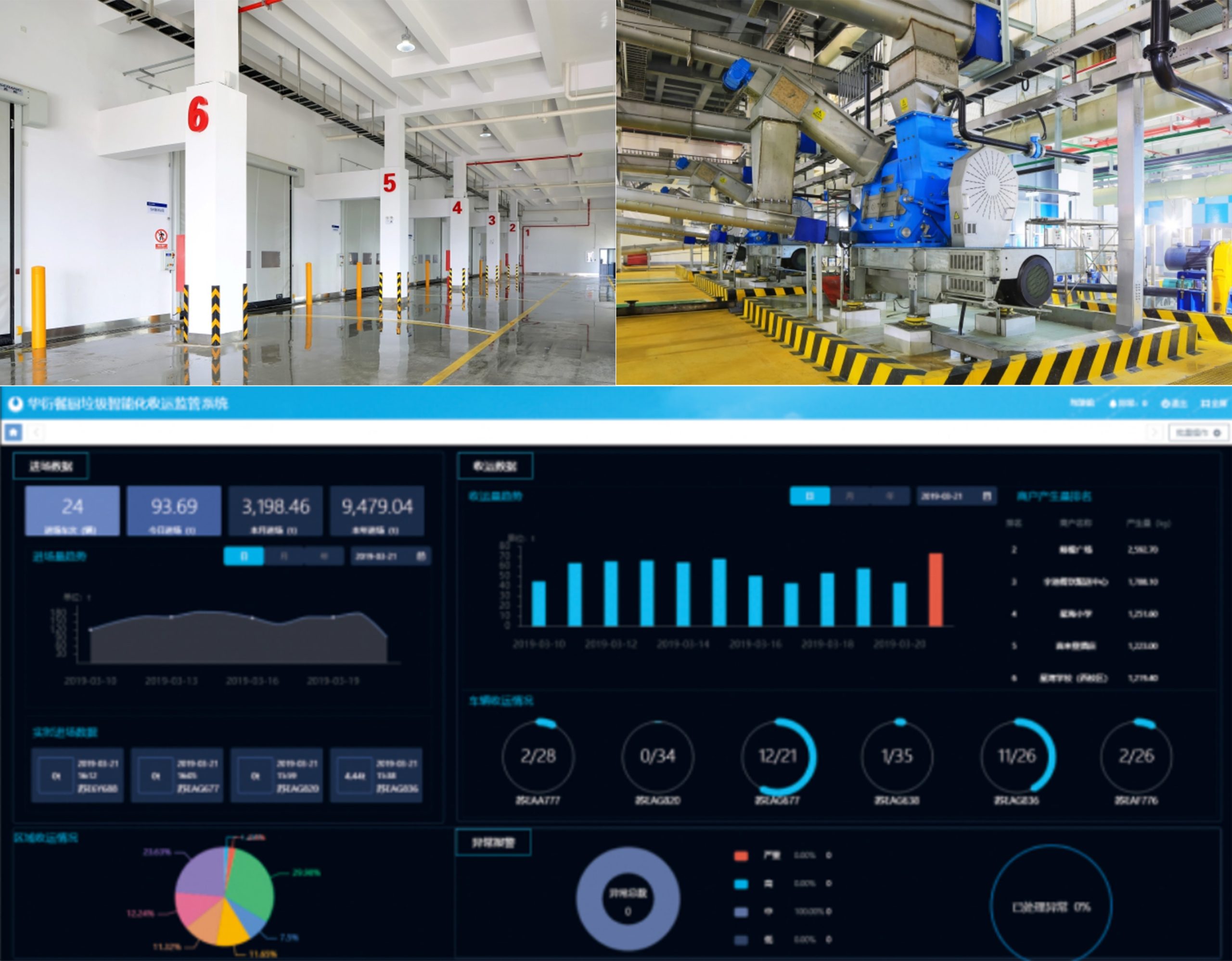

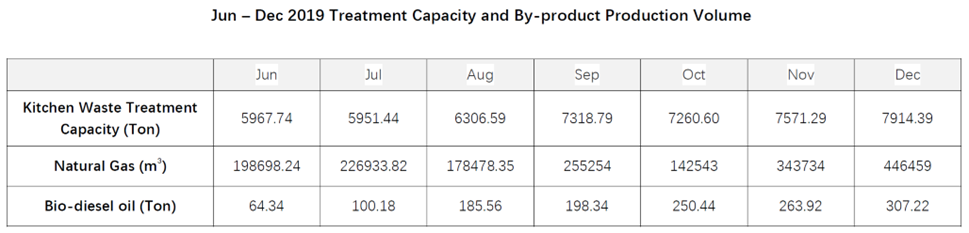

As a key carbon reduction development project in Suzhou (city next to Shanghai in China) and one of the Suzhou Industrial Park’s environmental protection projects, first phase of the organic waste treatment project in Suzhou Industrial Park has been put into operation since end of 2018.

With the gradual increase in waste collection volume, the first phase project has reached full capacity. Meanwhile, Suzhou has enforced garbage classification since June 1, 2020, considering environmental protection and economic benefits, second phase of the project had launched as expansion.

A new processing capacity of 300t/d of food waste is added. The main process flow is: receiving hopper + double-shaft crushing + trommel screen + organic matter crushing + extrusion + slurry sand removal + anaerobic digestion + biogas upgrading to bio-CNG (pipeline natural gas with methane concentration ≥97%). This project can effectively achieve the “harmless”, “reduce” and “resource utilization” treatment of kitchen waste, and reduce odor, wastewater and solid waste pollution of kitchen waste. It is a green and low-carbon cycle development and accelerate the need for industrial transformation and upgrading, also realizes the recycling and utilization of resources in multiple links such as organic waste treatment, sludge disposal, biogas utilization, and organic fertilizer production, this project has become a resource recycling demonstration park with great demonstration value in China.

Since ‘Adekom’ Containerized Weather Proof VSD Biogas Screw Compressor KF220(G)INV-8 with gas capacity 1445 Nm3/h @9 bar.g working pressure supplied for this Suzhou Industrial Park kitchen waste treatment phase I project in 2018, it has been stably operating on 24/7 basis to plant owner satisfaction until now and for the second phase of the project, another similar design ‘Adekom’ biogas screw compressor KF250(G)INV-9 with gas capacity 1600 Nm3/h @ 9 bar.g working pressure has been installed. Different from traditional reciprocating piston compressors or natural gas compressors used for biogas, these biogas screw compressors are fitted with European imported screw compressor gas-end specifically designed for biogas application. Matured biogas screw compressor design has been proved to be technological advance, safe and reliable in operation for more than 100 projects worldwide under different climatic conditions and handling different gas sources during the past decades. This has been assuring stable and reliable gas source for PSA (pressure swing adsorption) upgrading equipment in this project for producing bio-methane continuously with concentration of 98% entering the Hong Kong and China Gas Company pipeline network.

For more information and biogas projects, read BiogasWorld’s Canadian Biogas Magazine.