Screening Technology – Rotorrake

The Börger Rotorrake is used in biogas plants to reduce coarse solids and fibrous material in substrate streams before pumping or transfer between digesters. Installed on the suction side upstream of pumps, the Rotorrake chops and conditions silages, manure, and organic waste, helping prevent pump blockages and reduce wear on downstream equipment. This supports reliable operation between digestion stages while maintaining long service life and easy maintenance in demanding biogas applications.

Description

Rotorrake – Endless Power for Coarse Solids

The Rotorrake tackles macerating tasks where other macerators reach their limits – for macerating very coarse solids and rags.

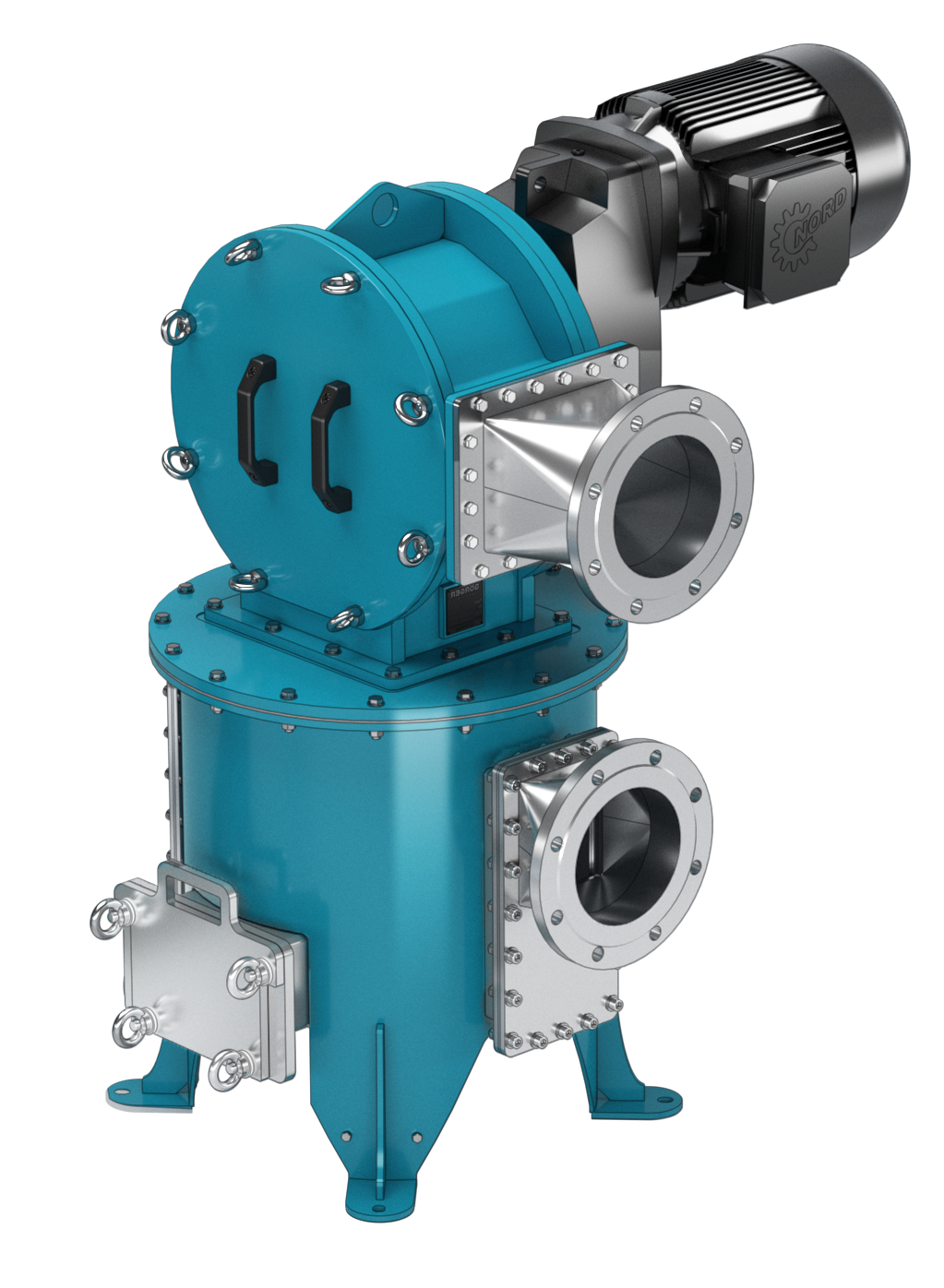

The single-shaft macerator is available with or without a debris collector.

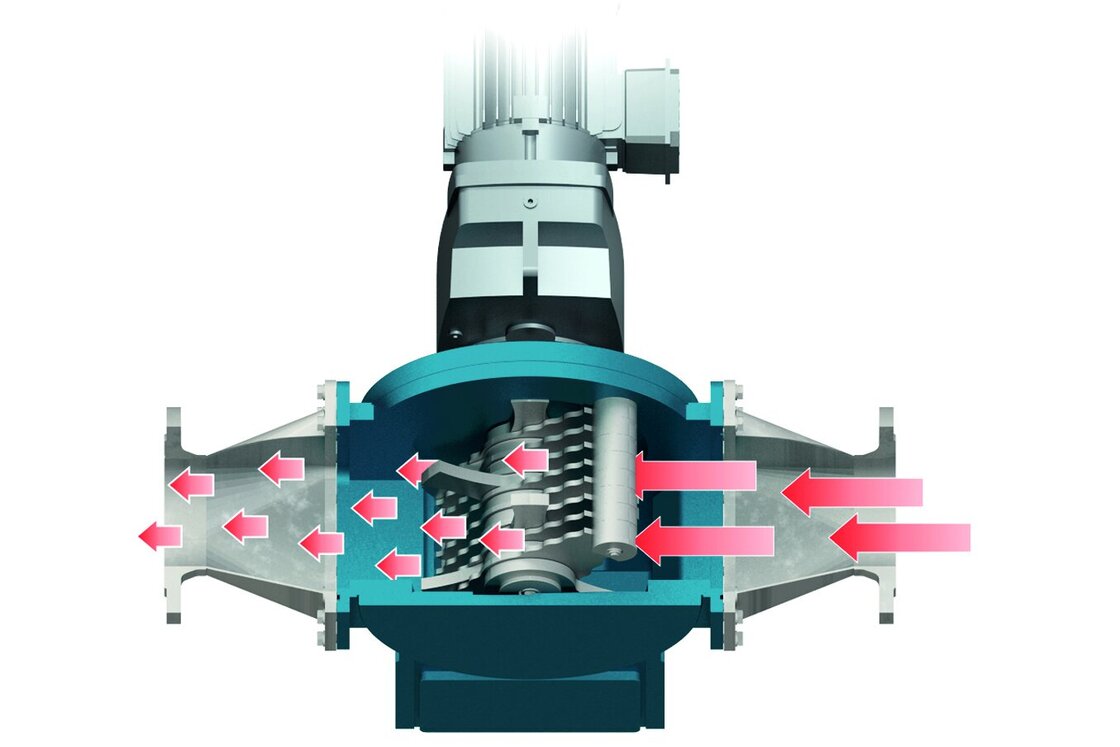

Rotating blades are also able to shred coarse solids

The liquid fed in with the solids flows through the stationary counter blades, which are arranged at an angle. The solids are captured by the counter blades and shredded by the rotating blades.

The macerated solids then continue to flow with the liquid.

Coarse objects that cannot be chopped are ejected into the debris collector.

Reliable technology

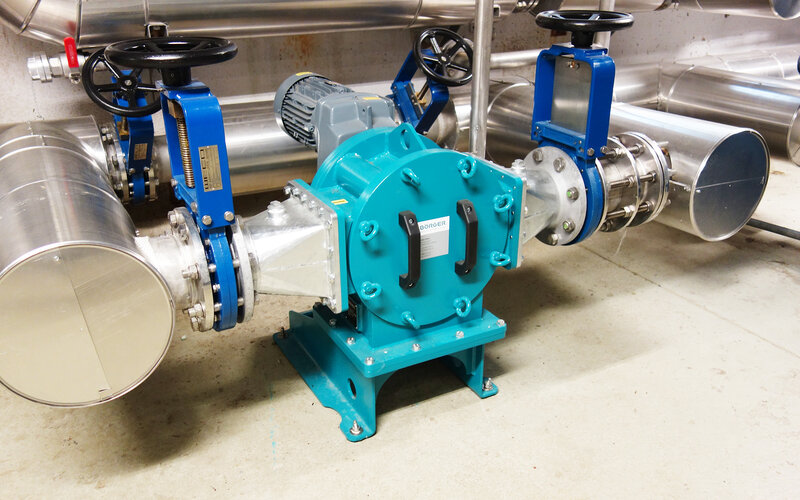

The Rotorrake protects pumps and systems technology from solids. It can be integrated in almost any existing system. Retrofitting of the macerator is also possible.

The best solution for your application

Depending on the application, the Rotorrake is installed with or without a foreign body separator (16 L or 150 l). When operating conditions change, the debris collector can be retrofitted, replaced or removed.

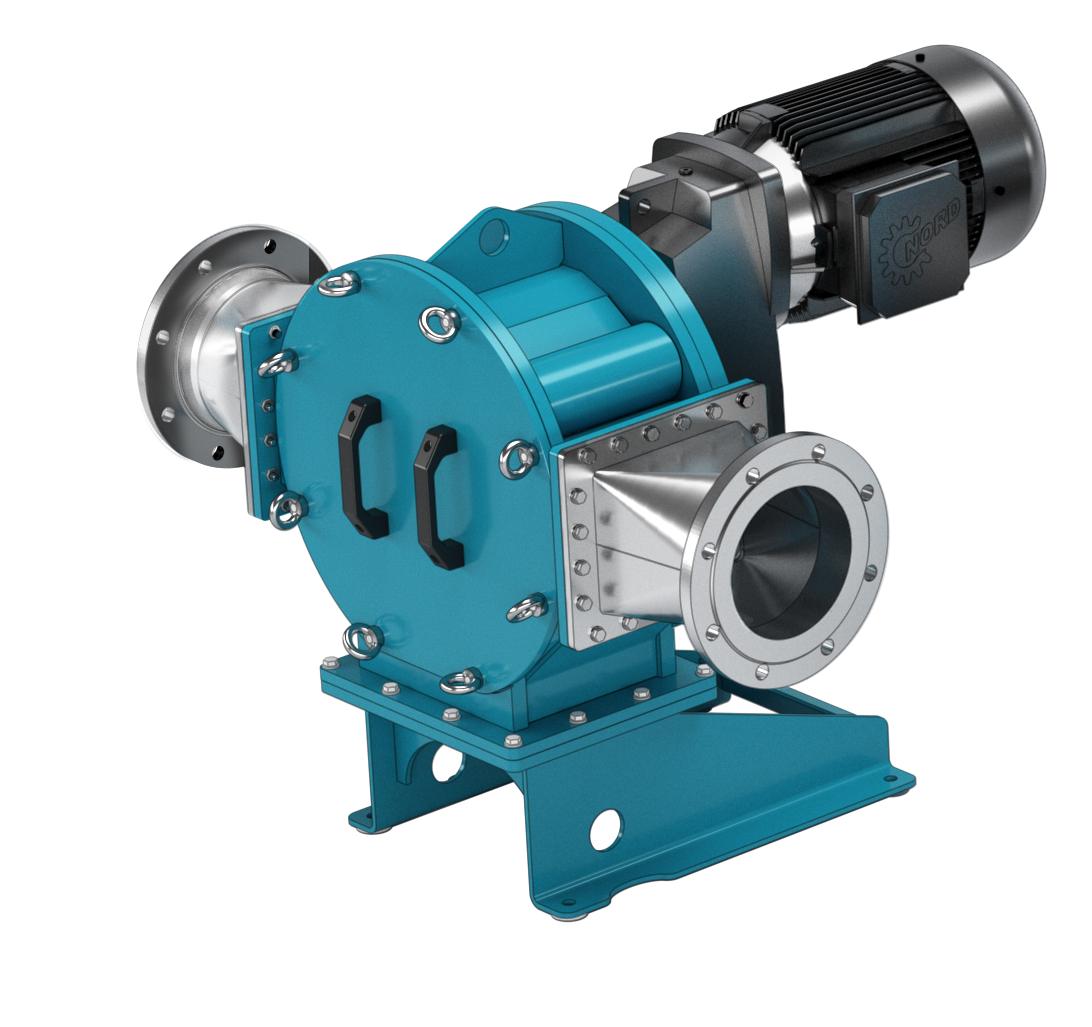

Rotorrake pure

The Rotorrake pure dispenses with a debris collector. It is used when the fluid does not contain solids that cannot be shredded (e.g. metal parts, stones).

Rotorrake plus 16

The Rotorrake plus 16 comes with a 16 L debris collector. Here, solids that cannot be shredded are collected.

The debris collector can be emptied very easily through a maintenance flap.

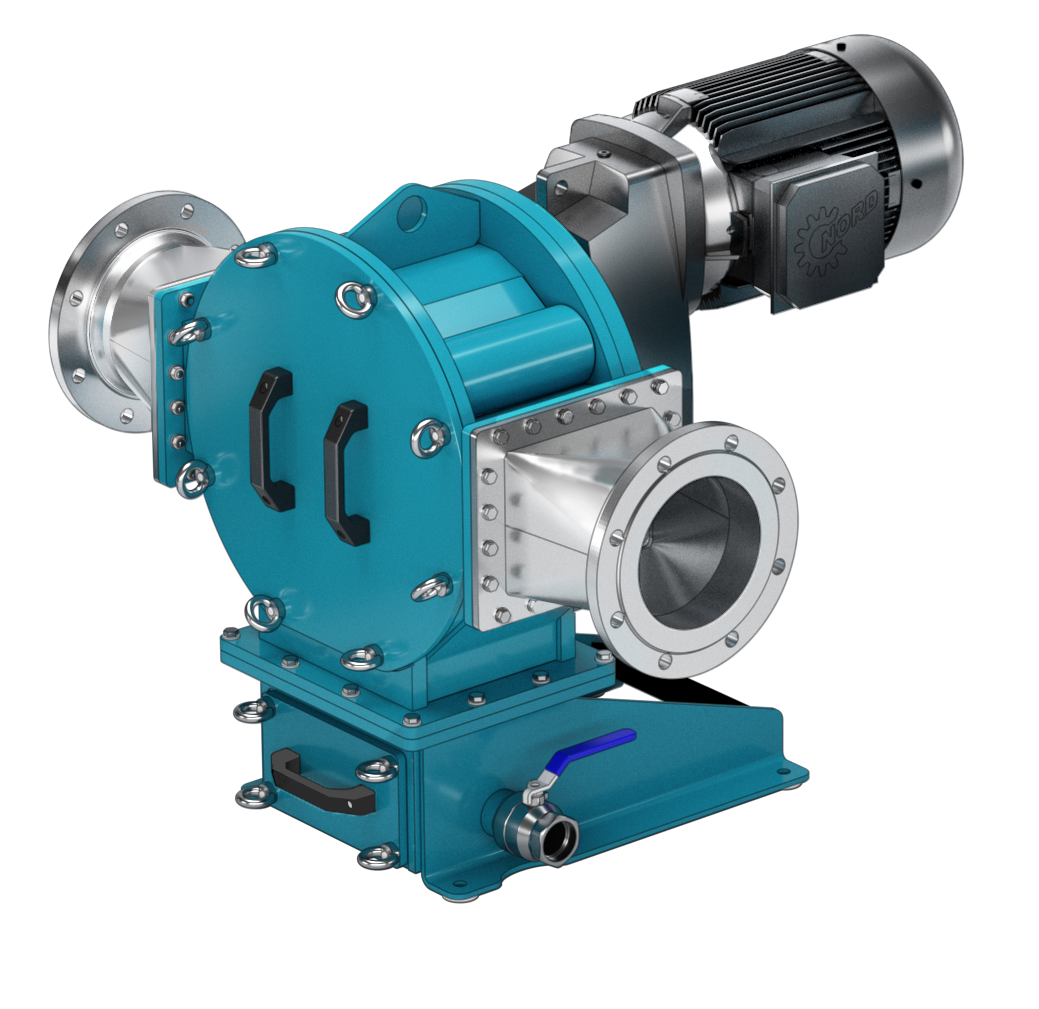

Rotorrake plus 150

The Rotorrake plus 150 is used, when the fluid contains large amounts of solids that cannot be shredded.

The 150 l debris collector can be emptied easily through a maintenance flap.

Tremendous power

The powerful chopping force of the Börger Rotorrake allows it to tackle tasks where others have failed – for chopping very coarse solids and blockages. Some of its key benefits include:

- Best cutting results: The Rotorrake reliably macerates coarse solids and rags without problems.

- Two sizes: The Rotorrake is available in two sizes. Both sizes are available with or without debris collector.

- Resistant to wear and energy-efficient: The Rotorrake is very energy efficient and resistant to wear, since the blades and counter blades are arranged in such a way that they do not come into contact with each other.

- Flexible installation: The Rotorrake offers high flexibility for installation. The flow direction can also be changed subsequently.

- Sophisticated control technology: Upon request, our electrical engineering department produces and programs a control technology that is perfectly matched to your requirements.

- ATEX: The Börger Rotorrakes can be used in potentially explosive atmospheres in accordance with the ATEX Directive.

- Easy maintenance: The quick-release cover and one-sided bearing allow fast direct access to the interior. The blades or counter blades can be turned around or replaced if required in this way.

A vital part of many companies for years

By the late nineties, we had completed the Rotorrake design for use in special applications. The macerating concept was convincing. Since then, we have continuously developed the Rotorrake.

The Rotorrake ensures smooth operation in numerous installations for sludge, anaerobic digestion circulation, silages, and pumping station.